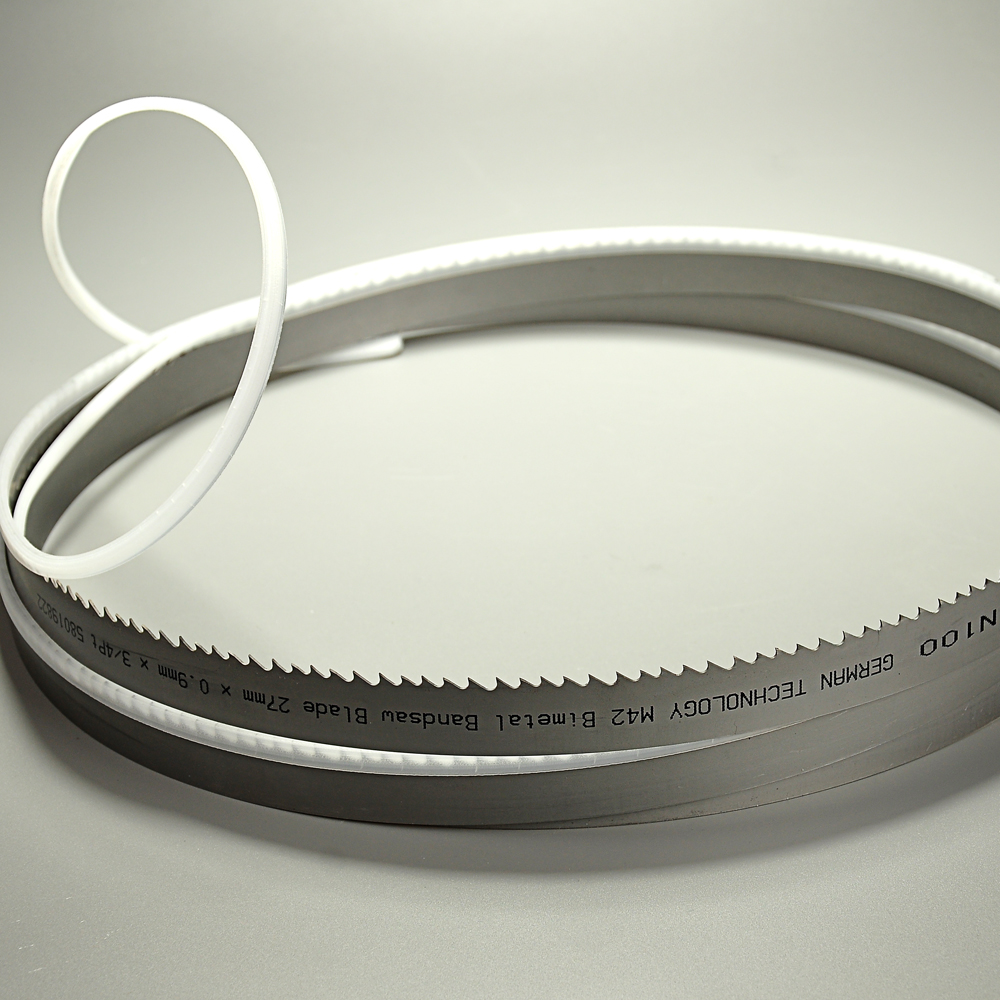

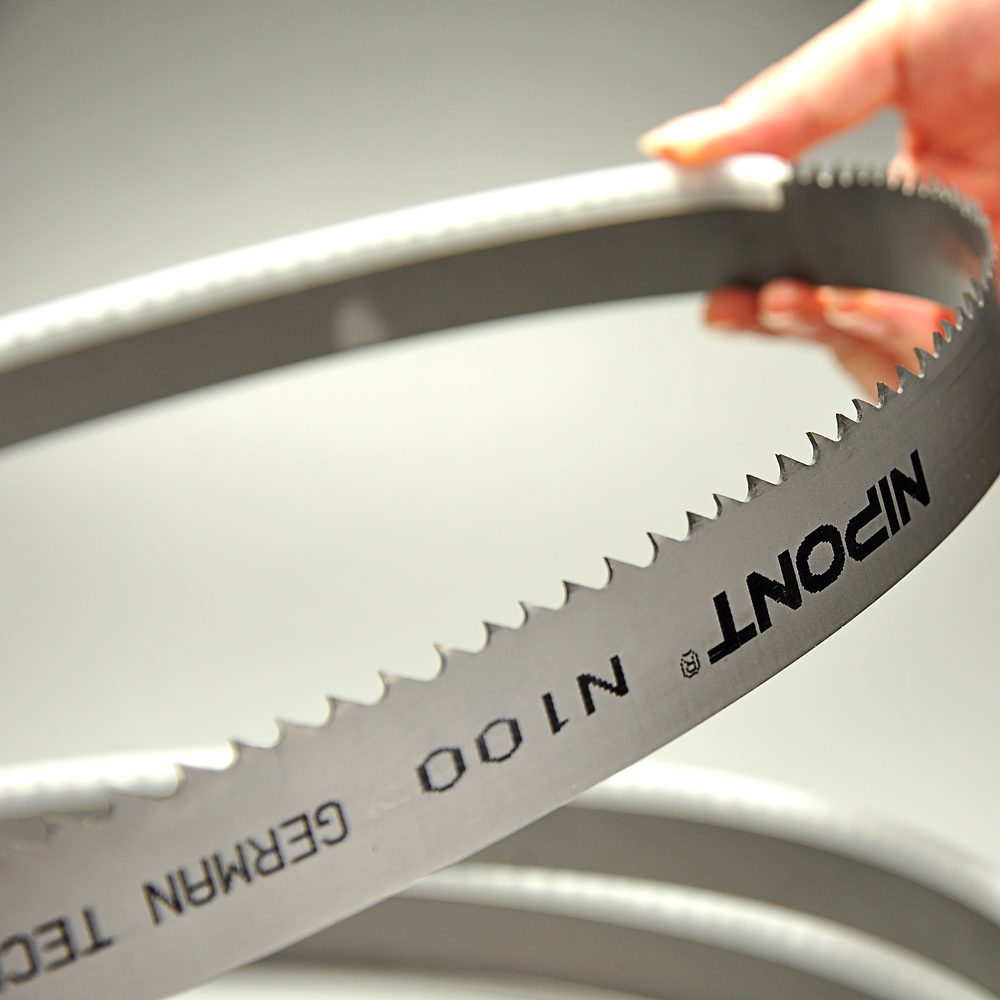

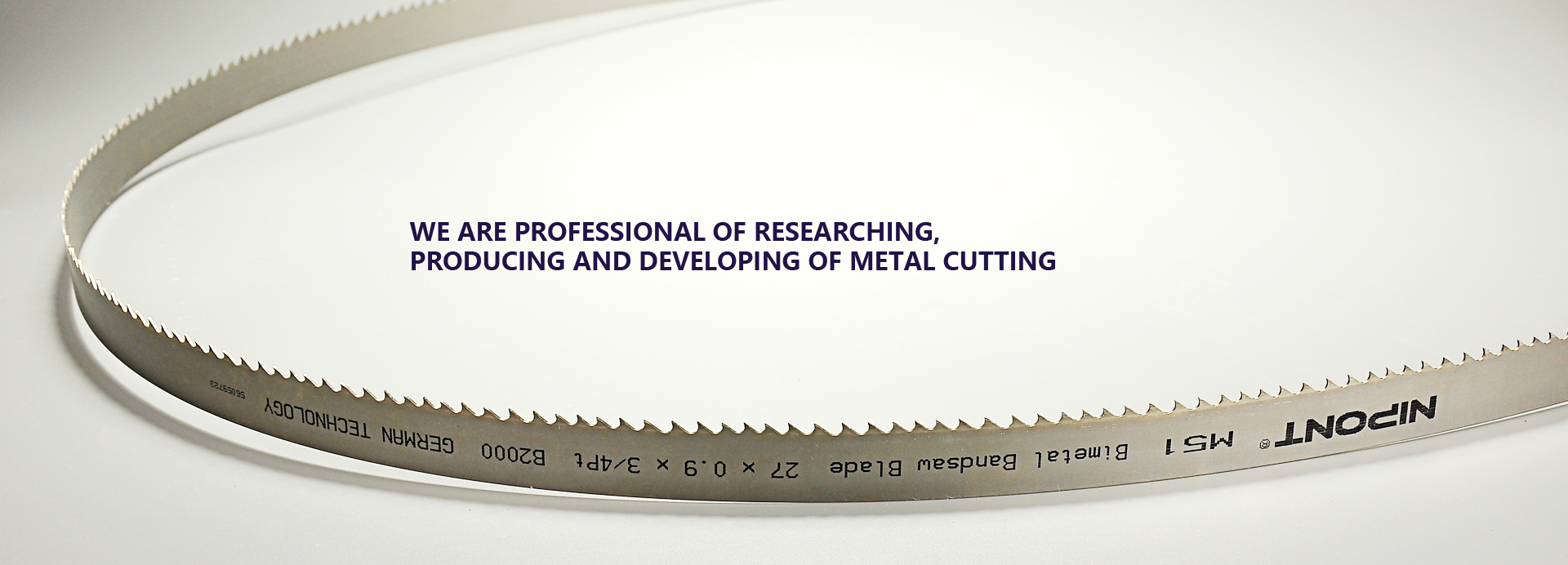

Imported high speed steel M42 with high content of cobalt as the tooth material, greatly reducing the the content of the primary carbide, improve the tooth material hardness and toughness after heat treatment, the hardness reaches 68-69HRC.The imported backing material containing 4% chromium, provides the fatigue life of higher strength and longer.The patent technology of heat treatment, greatly improve the tooth of the red hardness and wear resistance.

High-class quality Bimetal band saw blade at reasonable price to satisfied with majority of dearlers and users.

mm | Inch | TPI | ||

13x0.9 | 1/2X0.025 | 14, 10/14, 8/12, 8/11, 6/10, 4 | ||

19x0.9 | 3/4X0.035 | 14, 8/12, 8/11, 6/10, 6, 5/8,5/7, 4/6, 4 | ||

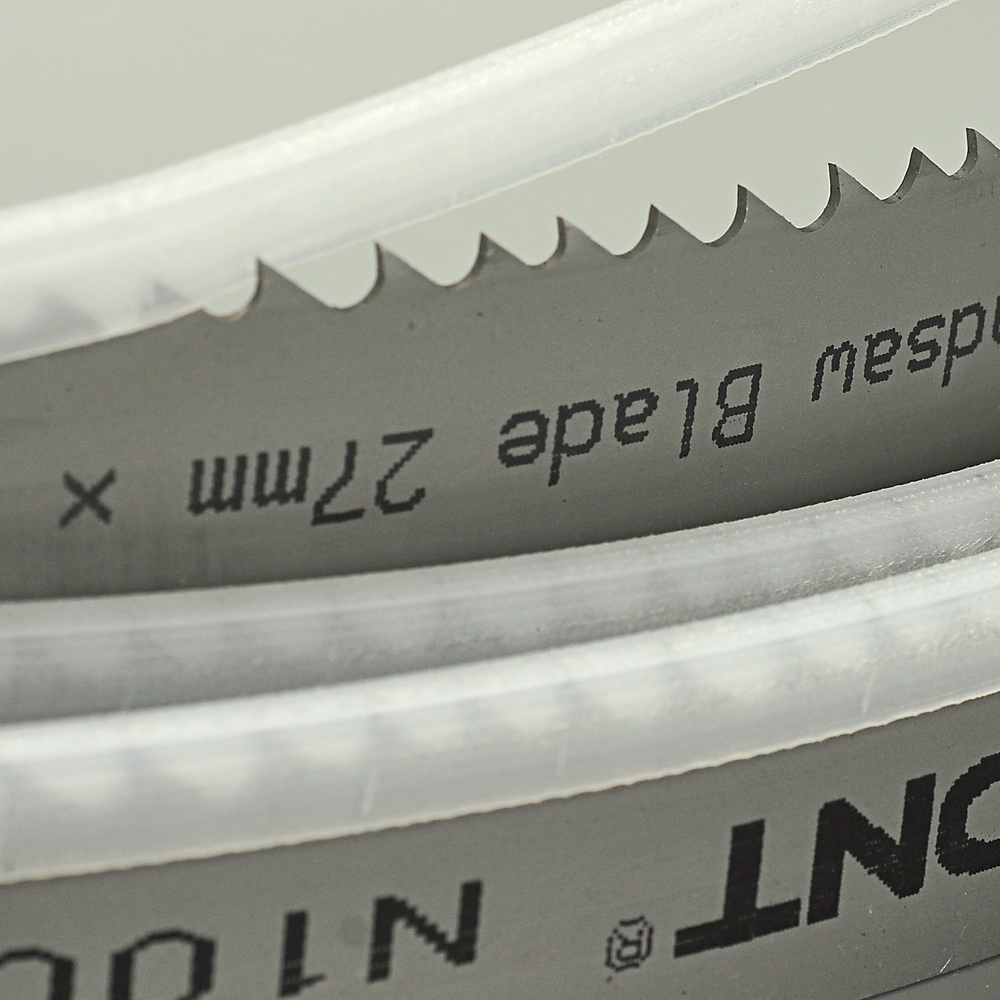

27x0.9 | 1x0.035 | 14, 10/14, 8/12, 8/11, 8, 6/10, 5/8,5/7, 4/6, 4, 3/4, 3, 2/3 | ||

34x1.1 | 1 1/4x0.042 | 8/12, 6/10, 6, 5/8,5/7, 4/6, 4, 3/4, 3, 2/3 | ||

41x1.3 | 1 1/2x0.05 | 5/8, 4/6, 3/4, 2/3, 1.4/2, 1.0/1.5 | ||

54X1.6 | 2x0.063 | 4/6, 2/3,3/4,0.75/1.25, 1.4/2.0, 1.0/1.5 | ||

67x1.6 | 2 5/8x0.063 | 2/3,3/4,0.75/1.25, 1.4/2.0, 1.0/1.5 | ||